Flow Nozzles

Flow Nozzles

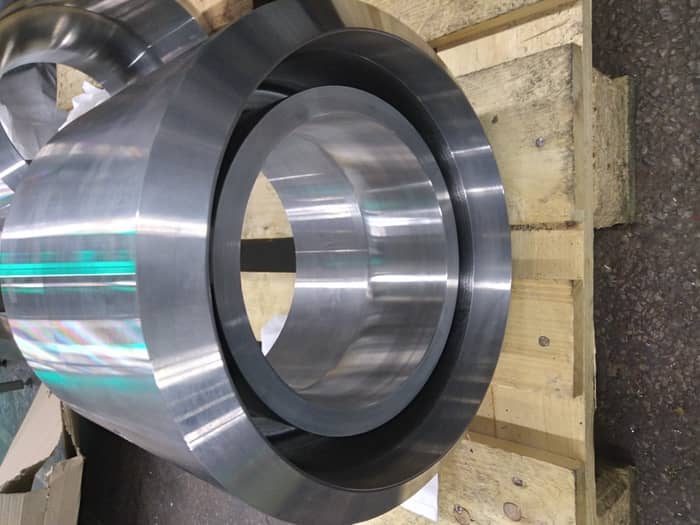

EMI manufacture high-quality flow nozzles as part of their comprehensive range of industrial fluid measurement solutions. Our flow nozzles are meticulously engineered to ensure accurate and reliable measurement of fluid flow rates in various industrial applications. With a focus on precision and quality, EMI’s flow nozzles are designed to meet the stringent demands of industries such as oil and gas, chemical processing, water treatment, and more.

Our flow nozzles are available in a range of sizes and materials to suit different operating conditions and fluid types. Each nozzle is carefully calibrated and tested to deliver precise flow measurements, helping our customers optimize their processes and improve efficiency.

Specifications

Flow Nozzles can be designed to suit a range of applications:

- Measurement of gases, steam, liquids and slurries

- Many options for materials of construction*

- 3.1 or 3.2 Materials Traceability & NACE Compliance

- ¼”NB 48″NB [DN8 to DN1200]

- ASME, API, PN Rated Process connection to suit all requirements

- Design Pressures & Temperature to customer requirement

- Non-Destructive Testing

- Calibration

- PED Compliance

Materials

- Carbon Steel grades

- ChromeMoly Steels (F9, F11, F22, F91 etc.)

- Austenitic Stainless Steel Grades (300 Series: 316, 304, 310 etc.)

- Duplex/Super Duplex Grades (F51, F53, F55 & F60)

- High Moly Stainless Steel (F44)

- Hastelloys (C22 / C276 / B3)

- Inconel® Grades (Alloy 600 / Alloy 625 / Alloy 718)

- Incoloy® Grades (Alloy 800 / Alloy 825)

- Monel® (Alloy 400)

- Cupronickel

- Titanium

- Tantalum, Zirconium

FAQs

What is a flow nozzle, and how does it work?

A flow nozzle is a type of differential pressure flow meter used to measure the flow rate of fluids in pipelines. It operates based on the principle of creating a pressure drop across a constriction in the flow path, allowing for accurate determination of flow rate through calibrated equations.

What are the advantages of using flow nozzles over other flow meter types?

Flow nozzles offer several advantages, including high accuracy, low susceptibility to erosion or damage from abrasive fluids, and minimal maintenance requirements compared to other flow meter types such as orifice plates or venturi tubes.

How do I select the right size and material for a flow nozzle?

The selection of the flow nozzle size and material depends on factors such as the flow rate, fluid properties, temperature, and pressure conditions. Our engineering team can assist you in determining the optimal size and material for your specific application requirements.

Can flow nozzles be installed in existing pipelines, or do they require special considerations?

Flow nozzles can typically be installed in existing pipelines with minimal modifications. However, proper installation practices, including positioning and orientation, are crucial to ensure accurate and reliable flow measurements.

What maintenance is required for flow nozzles, and how often should it be performed?

Flow nozzles generally require minimal maintenance. Regular inspection for signs of wear or damage is recommended, and any accumulation of debris should be cleaned periodically to ensure optimal performance. Maintenance intervals may vary depending on the operating conditions and fluid characteristics.