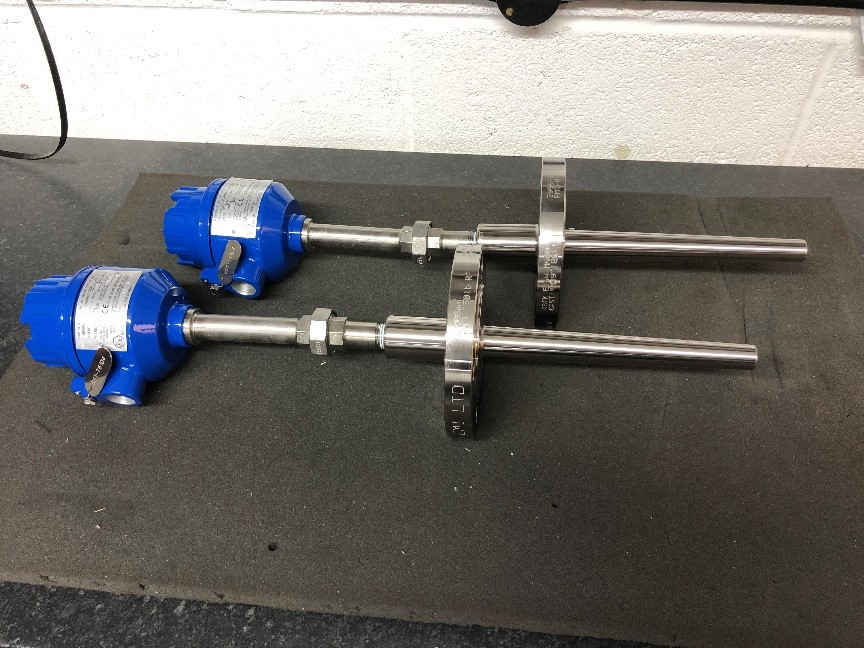

Flanged Thermowell

Flanged Thermowell

A flanged thermowell can provide a higher level of protection against highly pressurized, high velocity and corrosion resistance protection to the sensing device than a standard thermowell. We can manufacture a wide range of flanges which will provide a very secure seal for extreme pressure and corrosive environments.

Specifications

Thermowell Data Sheet

| Process Connection: | Flanged, Hub Connector, Screwed, Weld-in, Vanstone, |

| Type: | Solid Barstock, Single Piece Forged, Welded, Fabricated with Solid Tip |

| Nominal Pipe Sizes: | ½” – 4”NB / DN15 – DN100 – Others available on request |

| Stem Type: | Parallel, Tapered, Stepped |

| Stem Diameters: | 10+ mm |

| Bore Diameters: | 3 mm – 25 mm – Single or Multiple [Single bore 6.6mm most common] |

| Lengths: | Up to 1200mm overall solid drilled as single piece – Others options available |

| Instrument Connection: | Male or Female Threads: NPT-F, BSP, Metric Threads

[½”NPT-F Most common] |

| Material Grades: | Carbon Steel grades

ChromeMoly Steels (F9, F11, F22, F91 etc.) Austenitic Stainless Steel Grades (300 Series: 316, 304, 310… / 400 Series.) Duplex/Super Duplex Grades (F51, F53, F55 & F60) High Moly Stainless Steel (F44 / 6-Mo SS) Hastelloy (C22 / C276 / B3) Inconel® Grades (Alloy 600 / Alloy 625 / Alloy 718) Incoloy® Grades (Alloy 800 / Alloy 825 / Alloy 800H & 800HT) Monel® (Alloy 400 / 500) Cupronickel (70/30 & 90/10) Titanium (Grade 2 – Grade 5) Tantalum, Zirconium |

| Material Certification: | EN10204 3.1

EN10204 3.2 NACE – MR0175/ISO 15156 & MR0103 requirements for sour gas applications NORSOK |

| Hardfacing/Coatings: | Stellite6, Ebonite Lining, Corrosion Resistant Coating. Other available on request |

| Sensors: | Thermocouples, Platinum Resistance Temperature Detectors (PT100), Bimetallic Sensors. Calibration of sensors available on request |

| Accessories: | Nipple/Union/Nipple arrangements, Connection Heads, Transmitters |

| Calculations: | Wake Frequency Calculations to ASME PTC-19.3 (latest version) |

| Conformity: | ATEX certified assemblies available |

Materials

- Carbon Steel grades

- ChromeMoly Steels (F9, F11, F22, F91 etc.)

- Austenitic Stainless Steel Grades (300 Series: 316, 304, 310 etc.)

- Duplex/Super Duplex Grades (F51, F53, F55 & F60)

- High Moly Stainless Steel (F44)

- Hastelloy (C22 / C276 / B3)

- Inconel® Grades (Alloy 600 / Alloy 625 / Alloy 718)

- Incoloy® Grades (Alloy 800 / Alloy 825)

- Monel® (Alloy 400)

- Cupronickel

- Titanium

- Tantalum, Zirconium

Flanged thermowells can be designed to suit the following applications:

- CNC Vertical Machining Centre

- Many options for materials of construction*

- 3.1 or 3.2 Materials Traceability & NACE Compliance

- PTFE/Ebonite/Stellite6 (or equivalent)

- Cladded

- ASME, API, PN Rated Process connection to suit all requirements

- Design Pressures & Temperature to customer requirement

- Non-Destructive Testing

- Wake Frequency Calculations to ASME PTC 19.3

- PED Compliance

Testing available on Thermowells:

- Hydrostatic Pressure Testing – External & Internal

- Radiography of Full Penetration Welds

- Liquid Dye Penetration Testing to PCN Level II

- Positive Material Identification

- Ferrite Content Measurement with Ferritescope Tester for Duplex Stainless Steels

FAQs

What is a flanged thermowell?

A flanged thermowell can provide a higher level of protection against highly pressurized, high velocity and corrosion resistance protection to the sensing device than a standard thermowell.